If you’re new to purchasing injection-molded plastics, you may be surprised when you read this post and discover all the hours required when making an injection mold.

Recently a poultry processing company approached HTI Plastics about manufacturing a poultry shackle. The part had been made overseas. But the company, based in Nebraska, decided it would be simpler to make the part locally. They use about 10,000 pieces each year.

Because they didn’t have the part model or any drawings, the first step was to reverse-engineer the part and create a 3D, computer-generated model. (If we were manufacturing a part for the first time, we would typically produce a rapid prototype. Because we had a sample, this wasn’t necessary.) The time involved in this part of the project was approximately 35-40 hours.

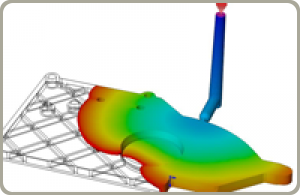

Once the customer approved the computer-generated model, we prepared to make the mold. It took our engineer about 40 hours to design the mold. There are hundreds of steps involved, ranging from deciding where the parting line of the mold should be (where the mold cavities will meet) to determining the thickness of the steel plates used in the mold. Other steps include examining other actions in the mold. Which way should the mold split/open? Are there features of the part that require core pulls or threads that need to be unscrewed?

Once the design work was finished, the engineer began to spec the materials needed to making an injection mold. These materials are selected based on the part to be manufactured and the usage of the mold. The poultry shackle was made of polyethylene, a non-abrasive material. By contrast, a part we manufacture out of a fiberglass-filled plastic for an agriculture client requires a heavier-duty, more wear-resistant steel for the mold because over time fiberglass wears away steel.

Once the materials arrived, we were ready to build the mold. We used our computer-aided design program to write the code that instructs the equipment on how to cut the steel to create the pieces used in the mold. This programming work took 40-50 hours.

The poultry shackle is about 6” wide by 4” tall and 2” deep. The mold used to manufacture the shackle is comprised of about 60 parts. Machining these parts took 175-200 hours over several weeks. During this process our project manager sent weekly updates to our customer.

After the machined steel components were made, we assembled them, every piece in place, like a large 3D puzzle. The pieces of each mold have to fit together precisely — some with a gap of only 0.0005”. (Imagine slicing the thickness of a piece of ordinary paper into five separate sheets.)

Once the mold passed inspection by our inspection team, it was time to try it and create a first article. After we created a few samples, our engineer took measurements to ensure the parts meet the specifications for the product. We just sent the samples to our customer for approval. After the customer approves them, we’ll schedule the first production run.

If you have questions about injection molds, please let us know.