The Principles of DFM: Designing for Manufacturability;

HTI Plastics Optimizes for Excellence in Mold

In the continuous pursuit of perfection in part design, HTI Plastics adheres to a holistic philosophy, ensuring without exception that every aspect of a design is thoroughly evaluated and optimized in the early phases of the design process. The definitive goal of this scientific approach is to enhance profitability for our manufacturing partners, which in turn ensures the continued growth and success of HTI. To this end, the company has taken decisive steps to advance this singular objective.

Designing for Efficacy

Each finished part must meet requirements as expected, every time. Specific testing of a part’s manufacturability is ongoing during every stage of the process. Aspects such as critical tolerances, maximum displacement, strength, hole sizing, and material comparisons are constantly evaluated and updated. Any modification to the design requires a thorough computation of its impact on the three F’s of the plastic molding industry: Form (size, shape, balance, etc.), Fit (interaction with other components), and Function (applied purpose) of the part. HTI ensures that these criteria are met while maintaining speed and efficiency to keep costs low.

Cultivating a Pioneering Workforce

HTI searched for the best solutions to maintain these standards of excellence and decided to invest in an ongoing training program teaching the science of systematic molding. Our staff of engineers is continuously updated on cutting-edge methods and technologies for process control and the evaluation of process data. How is this data collected? HTI has some of the industry’s most robust analytical tools available for this purpose.

The Best in Analytical Tools

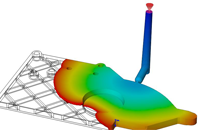

HTI has integrated powerful prototype simulation and mold flow analysis computer programs into its design processes. As mold and material data are fed into the programs, diagnostic reports provide immediate information on the design’s manufacturability—from conformity within tolerances and fatigue strength to flow behavior and cooling rates. The software also supplies troubleshooting information and advice on design improvements where applicable. With the capability of analyzing multi-cavity molds and estimating cycle times, these programs help, in short, to save time and money while creating the best possible parts with built-in repeatability.

A Culture of Excellence

As always, HTI’s secret weapon remains its stellar workforce. The most advanced technologies are still only as good as the people who use them. HTI’s vast experience and unrivaled creative thinkers have set the standard for excellence in the plastic injection mold industry. Our manufacturing principles continue to build confidence and profitability with our clients, giving them the edge they need in this competitive market.