Manufacturing plastic products using injection molding, for industries of pharmaceutical applicators, firearms, container lids, and custom products.

HTI Plastics is a highly skilled company dedicated to manufacturing injection molded plastics products, building high quality products, including plastic lids, pharmaceutical applicators, firearms, and custom products based on your needs, all while providing timely deliveries and creating an atmosphere of continuous improvements where all employees strive to keep both internal and external customers satisfied.

We take pride in being an OEM pharmaceutical/medical plastic injection molding company and contract manufacturer for your plastics products.

HTI Plastics understands that in today’s world you need a company that is knowledgeable within your industry, provides excellent customer service and high standards of injection molding manufacturing products. Our team of skilled engineers will work with you from inception throughout the lifetime of your project.

Looking for a price quote, Submit an RFQ and our team of professionals will respond promptly. We look forward to working with you on your next plastic injection molding project.

HTI Plastics is an ISO Certified Company.

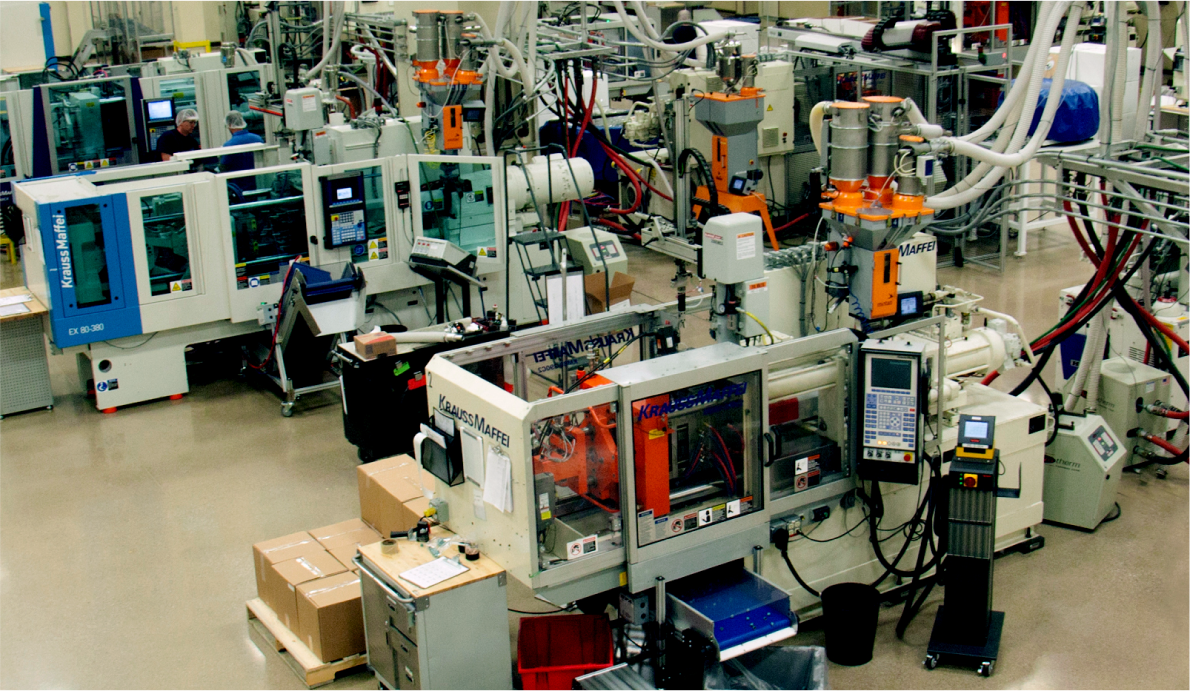

Take a “virtual tour” of our plastics manufacturing facility to learn more about our high-speed precision machines within our 100,000+ square foot, state-of-the-art molding facility.

MANUFACTURING SOLUTIONS.

INJECTION MOLDING FOR PLASTIC PRODUCTS.

A state-of-the-art manufacturing facility with 25 Krauss Maffei injection molding machines, 5 Sodick molding presses, and 1 Engel molding press, combined that range from 55 ton to 1,800 ton. These German engineered presses offer outstanding precision, high quality, dynamic responses and the fastest dry cycle times in the industry. You’ll be happy with our custom injection molding and plastics manufacturing services.

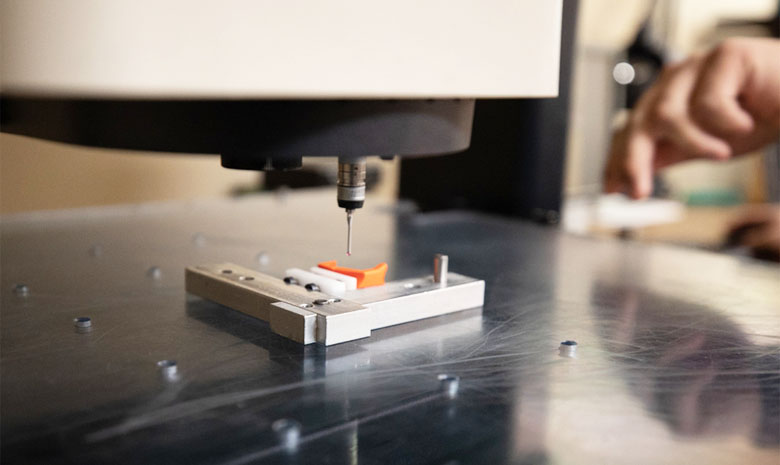

ENGINEERING FOR PLASTICS MANUFACTURING.

Our engineers are dedicated to designing for manufacturability. They have developed expertise in the field from years of creating products using a wide range of materials, design requirements and manufacturing challenges. Our engineers fully support our customers in every phase of the project. We’re detail-oriented to each projects specifications to deliver a design that is moldable.

SECONDARY / PACKAGING OPERATIONS.

Keeping secondary operations in-house allows us to provide our customers with high quality products at a fair price. Our state-of-the-art facility includes two clean assembly environments for FDA and GMP product lines, with the latest technologies and stringent quality control requirements.

We have a unique advantage that sets us apart from the standard injection molding manufacturer… our toolmakers. Our on-site tool and die manufacturing department allows us to reduce turnaround time on new production.

COMPANY NEWS.

Re-Certification for ISO 9001:2015 and ISO 13485:2016

Lincoln, NE – HTI Plastics, a leading injection molding manufacturing company, is proud to announce our achievement of re-certification for ISO 9001:2015 and ISO 13485:2016,. . .